ABOUT US

PAX MACHINE WORKS

ABOUT US

PAX MACHINE WORKS

THE HISTORY

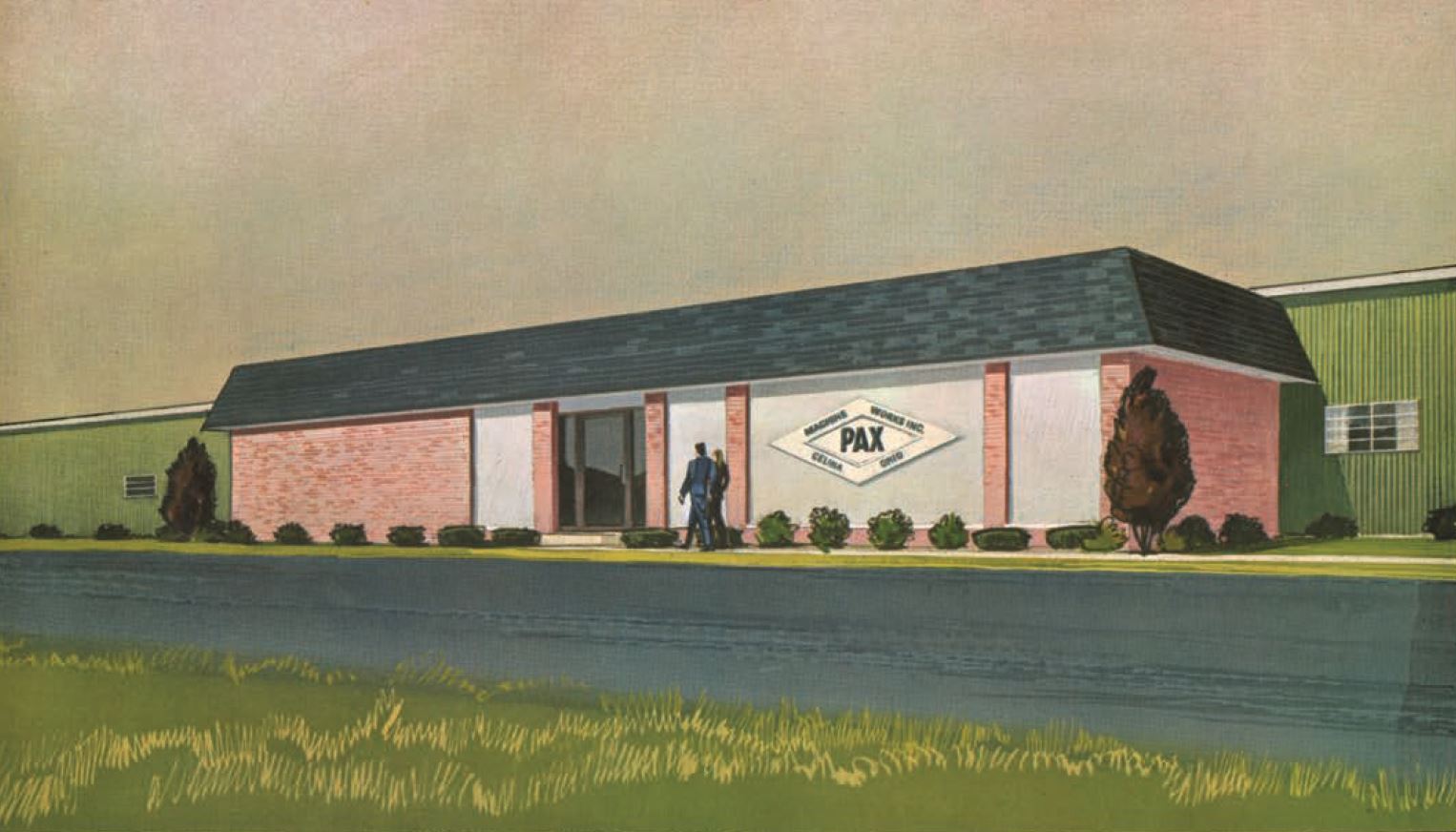

Founded in 1948 by Oscar Pax as a small repair shop serving local customers, Pax Machine Works, Inc. is now the premier source for high-quality precision metal stampings across the globe. To this day, it remains a family owned and operated business, dedicated to providing the highest quality parts and services for all our customers’ needs.

The Past

The Present

COMMITMENT TO QUALITY

Pax Machine Works is committed to not only maintaining but exceeding the quality expectations of our customers. This quality standard is upheld by continual investments in three major areas: plant, equipment, and the people that work here.

We also believe that we have a responsibility not only to our customers, but also our employees and our community in which we live. Pax provides a safe, clean working environment that is conducive for productivity and innovation. We also strive to remain a responsible member of the local community and actively participate in programs for the betterment of the community.

Pax Machine Works operates in a 455,000 square foot facility on a 160 acre property. Next to Pax Machine Works is our sister company, Pax Products, which operates in a 36,000 square foot facility.